Double Station Semi-Automatic MAP Modified Atmosphere Packaging Machine

MAP25DS Double Station model is designed to double production capacity. This model is built on the body of the base model that is combined with two drawers.

| MAP25DS |

|

We have built our reputation as the best service company in the industry based on demo, market test, service, training, emergency support, professional expertise and experience and of course the quality/reliability of our machines range.

We have been manufacturing and designing our machinery, down to the smallest component, using our own expertise and knowhow since 2008. The machines we have manufactured comply with international standards and certification.

MAP-25DS is innovative designed by APACK Team for vacuum drawing and gas flushing in one go and sealing tray with top film while tray is under pressure.

MAP-25DS is compatible for remote access option to control the MAP-25DS’s electric – electronic and mechanic system via internet.

MAP-25DS Double Station- Model requires two operators.

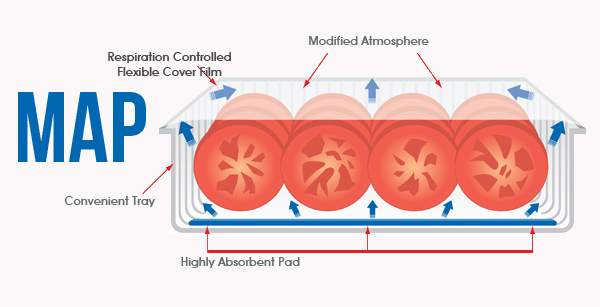

MAP-25DS tray sealer hermetically seals special plastic containers using a flexible film. While sealing, a good level of vacuum can be reached inside the container as well as the insertion of different types of inert gases.

MAP-25DS can handle also the entire production of most small and medium businesses in vegetarian or non vegetarian snack food, confectionery and fresh cut vegetables.

MAP-25DS has own Zero2 Oxygene software. With this software, MAP-25DS take all Oxygen progressively out from the package.

Semiautomatic MAP-25DS thermal sealer unit is manufactured by high quality craft workmanship.

20 years of experiance to be exact, lies behind the APACK brand. We provide machinery and services to hundereds of companies in Turkey and abroad. We work in cooperation with over 800 scientists and technicians worldwide to innovate our machinery and solutions.

Your product is supposed to be presented as attractively and well-protected as possible.

| USAGE OF MAP25DS |

|

Our MAP25DSs machines have international certificates of conformity. We are certified for ISO22000 Food Production and ISO13485 Medical Equipment Production.

The MAP25DS has been designed for long uninterrupted productions, and is offered with service and separe parts with our APACK warranty both our national and international customers.

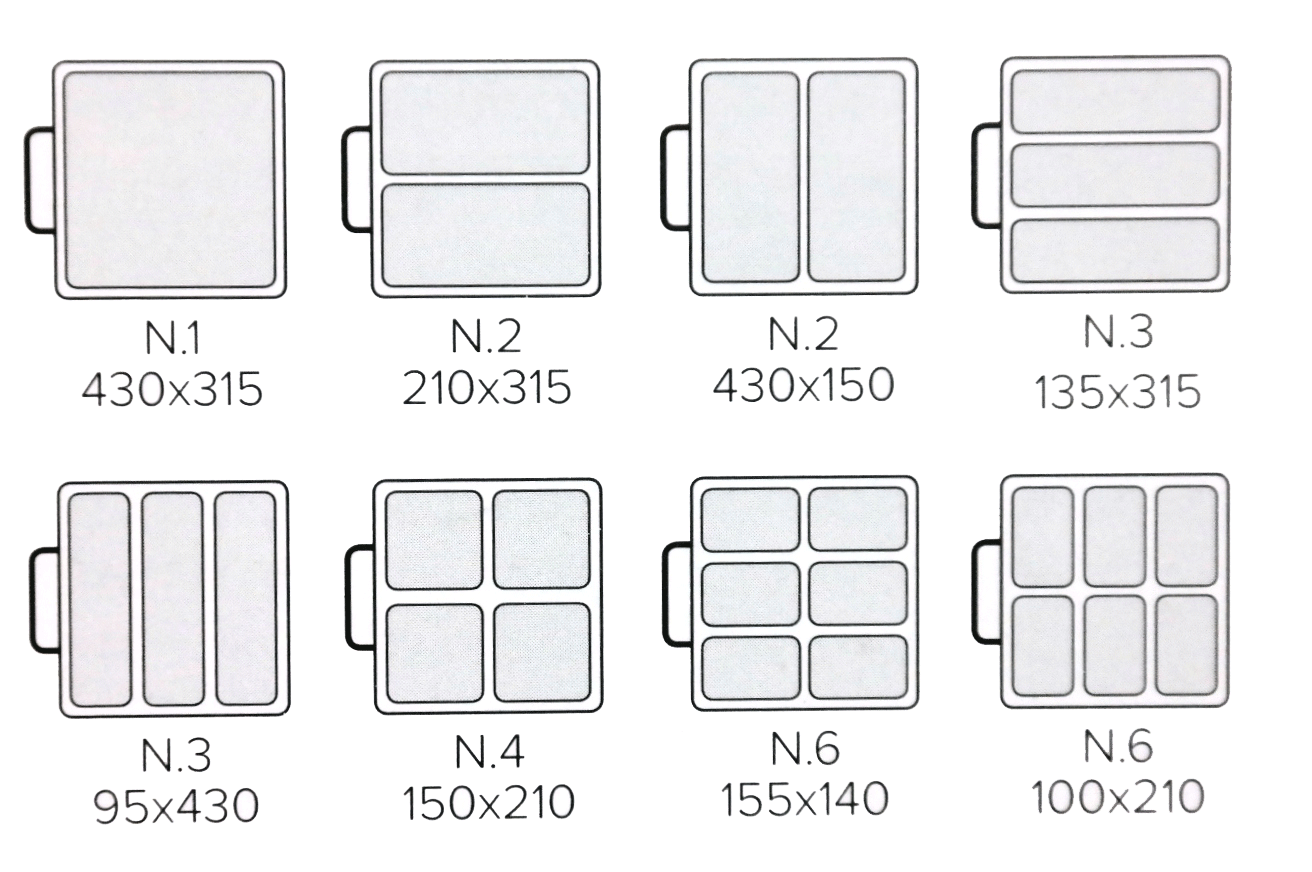

MAP25DS STANDARD TOOL SET

| MAP25DS TECHNICAL DETAILS | |

|---|---|

| POWER | 400V, 50-60Hz, 3/N/PE |

| POWER CONSUMPTION | 6kW maximum |

| VACUUM PUMP | 60m³/h |

| AIR PRESSURE CONSUMPTION | 8Nl/cycle, 6 bar Dry Air |

| GAS PRESSURE | 2‐6 bar |

| CONTROL SYSTEM | 7" Omron PLC Touch Screen |

| OVERALL DIMENSIONS | 800x1260x1770 mm |

| WEIGHT (with vacuum pump) | 400 kg |

| FILM WIDTH | 530 mm maximum |

| FILM ROLL DIAMETER | 76 mm maximum |

| PRODUCTION CAPACITY | 4-6 cycle/min (Vacuum and Gas) 8-10 cycle/min (Only Sealing) |

| OPERATION | Semi automatic with double drawer unit |

Modified Atmosphere Packaging, is a technology that has been developed to ensure that packaged food products stay fresh and attractive for as long as possible.

Modified Atmosphere Packaging, is a technology that has been developed to ensure that packaged food products stay fresh and attractive for as long as possible.

Everyone knows that a lot of factors cause food spoilage. The main causes is the growth of microbes such as bacteria, yeasts and mold. To keep food fresh for as long as possible without additives is our philosophy. While Sealing the food product in a package, containing gases in controlled proportions that makes slow down the process of oxidation and the growth of microbes.

| PRODUCT | MAP Life | Standart Atmosphere Life |

| Tost Bread | 2-3 Month | 10 Days |

| Cake | 40-60 Days | 10 Days |

| Patty | 6 Weeks | 1-2 Days |

| Pizza | 30 Days | 1-2 Days |

| Hamburger | 30 Days | 1 Week |

| Pita | 2-3 Months | 1 Month |

| Cheese | 6-8 Days | 3 Day |

This is the main idea of Modified Atmosphere Packaging = MAP.

Food is different - so is the gas composition used to pack different food products. Red meat needs high oxygen to maintain the red color, bread requires low oxygen to avoid mould and vegetables often need a three-gas mixture (gas flushing). Please ask for recommendation from your advisor to find the most suitable gas mixture (gas flushing) to perform better shelf life. Barrier films is more useful to prevent modified atmosphere from escaping or air getting back into the pack.